of rp_featop.jpg)

| Model | CIMM-200 |

| *Output | 50 to 200 Kgs. / Hr. |

| Rotor Assembly Diameter | 250 mm Approx. |

| Rotor Speed | 750 / 1500 / 2300 / 3000 RPM |

| Beaters | 12 Nos. knife and impact edges and 2 Nos. scraper blades |

| Screen dimension | Inner Diameter 260 mm / Height 135 mm |

| Motor | 3 Hp / 1440 RPM / 440 V. / 50 Hz. AC |

| Starter | "DOL" with reversible switch |

| Material charging height | 1445 mm |

| Material discharging height | 730 mm |

| Net weight (Approx.) | 275 Kgs. |

| Gross weight | 425 Kgs. |

| Machine Dimensions | 870 (L) x 965 (B) x 1630 (H) |

| Case Dimension | 1200 (L) x 1550 (B) x 1860 (H) |

APPLICATIONS

Multimill is widely used for wet and dry granulation, pulverisation etc. in Pharmaceuticals, Chemicals, Cosmetics, Ceramics, Colours, Dyestuff, Food products etc. It also finds application in Pesticides, Fertilizers, Spices, Detergents, Insecticides, Plastic and Resins Industries.

DESCRIPTION

Multi Mill unit consists of S.S. 304 quality hopper and processing chamber (can be provided is S.S. 316 quality at extra cost) with beaters assembly, motor, reversible switch, DOL starter, four speed step pulley, Suitable screen with painted pillar mounted on base plate, with castors.

OPERATION

Multimill operates on the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to get the required size reduction.

Material fed in the hopper, goes down to the processing chamber where it moves to the periphery and passes through the screen radially and tangentially. Finally the processed material gets collected in the container kept below the processing chamber.

Output and quality of the final product depends on three main factors

Shape of beaters (knife/impact edges),

Speed and Screen.

SALIENT FEATURES

Technical Specification

Turbo Sifter is used to sieve dry raw material in powder form before it is fed to Rapid mixer & wet granulator or High shear mixer.

The Turbo Sifter is suitable for separation of foreign objects from dry powder before mixing, One can use mesh size from 4 to 25. this machine is used for mainly screening the formulations (in form of dry powder) before feeding it in to the high shear mixer or Fluid bed granulator.

Turbo Sifter can also be mounted on castor wheel for mobility. Entire assembly and sieves can be removed for cleaning very easily.

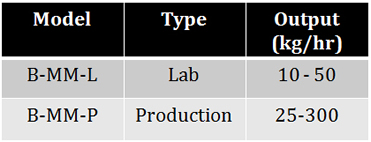

Capacity

Salient Features